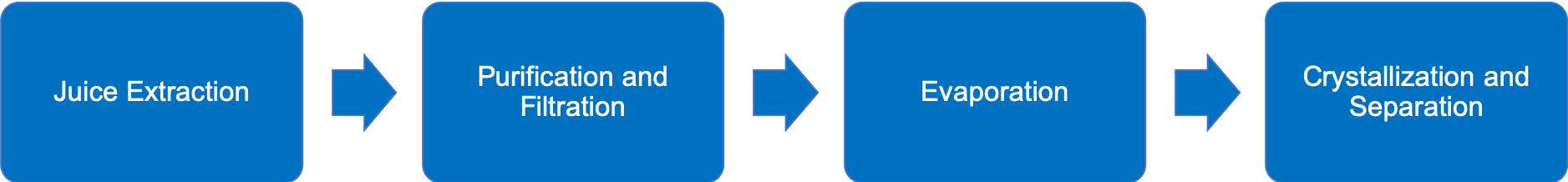

Full Range of Solutions for Filtration in the

SUGAR INDUSTRY

Sugar Industry - Filter Panels and Bags

Filtration is a critical process step in the sugar industry. Not only does it require extensive filtration expertise to choose and customize filter media, but also requires a close working relationship between the filter media supplier and the process team in the Sugar company.

Our Products for the Sugar Industry

Post Carbonation Filtration

Post Carbonation filtration process requirements are unique, requiring a balance between high flow rates and fine particle capture. Our range of fabrics for the process includes:

Monofilament and multifilament woven meshes in polyester and polypropylene fibers

Customized filter bags including round and rectangular leaf mesh - Polyester and polypropylene options - Custom fabrication solutions: - Round and rectangular leaf designs - snap covers

Desweetening

In the Sugar desweetening process, the residual sucrose is separated from the filter cakes. This has important bearing on the filter media and equipment choices. Rotary drum filters and filter presses are extensively used in this process.

We offer the following fabrics:

Monofilament and multifilament woven meshes in polyester and polypropylene fibers

Custom fabrication solutions: - FUSE coating - Rubber barrel neck options - Corner or center feed

Evaporation

Leaf Filter bags are extensively used during this process to catch the residual impurities left in the juice following evaporation. We maintain effective particle capture while ensuring high flow rates.

We offer the following products:

Monofilament and multifilament woven meshes in polyester and polypropylene fibers

Custom fabrication solutions: - FUSE coating - Rubber barrel neck options - Corner or center feed

Crystallization and Separation

After Crystallization, the sugar crystals must be segregated by the desired particule size, we provide a wide array of nylon and polyester meshes in 50- 5,000 micron sizes. Customized rectangular and . circular screens with strong rib supports ensure appropriate fitment, and longer life for the screens.

Request for Information

Please let us know of your filtration requirements or issues and we will get in touch with you.